Isolate valves are used in the conveying system of coal ash and dry powdery material, installed under the loading hopper, and play the role of cutting off materials during equipment maintenance by closing the valve plate.

Between the valve rod and sleeve pipe is double sealing structure to seal the inside and outside of equipment and prevent the leakage of material. Filter screen is set under the valve plate along with maintenance hand hole in the side. During the falling of materials from the upper side of the valve, big metal or non-metal project blocked by the filter screen can be picked up through the maintenance hand hole to protect the surface of equipment (dome roof of dome valve, double disc valve) under isolate valve from being damaged.

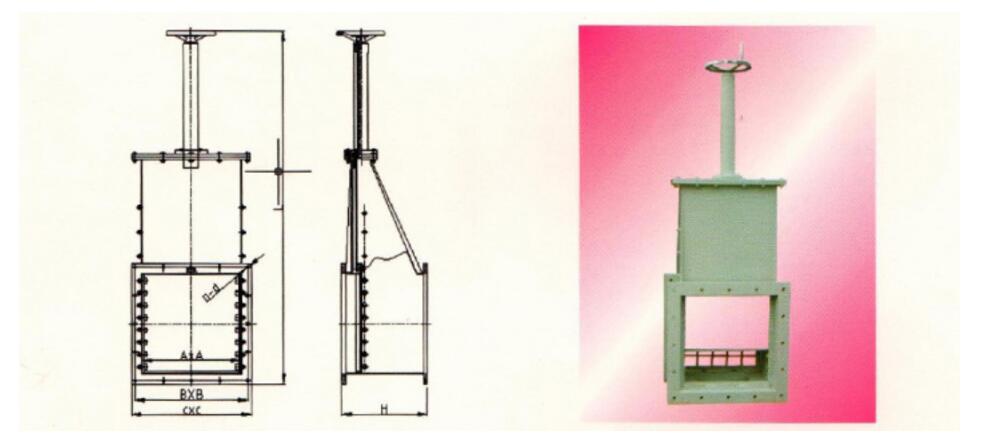

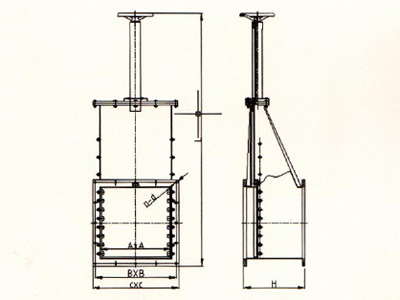

The closing stroke of isolate valve plate can be directly told from the running mark at the lower part of casing. This kind of isolate valve is driven by hand wheel, if the installation position is 2m above the ground, using chain wheel to replace the hand wheel, or using pneumatic or motor drive required by the customers and achieve remote or local control.

The material of isolate valve differs from different applications; it has the advantages of reasonable design structure, light weight and beautiful appearance.